-

Features

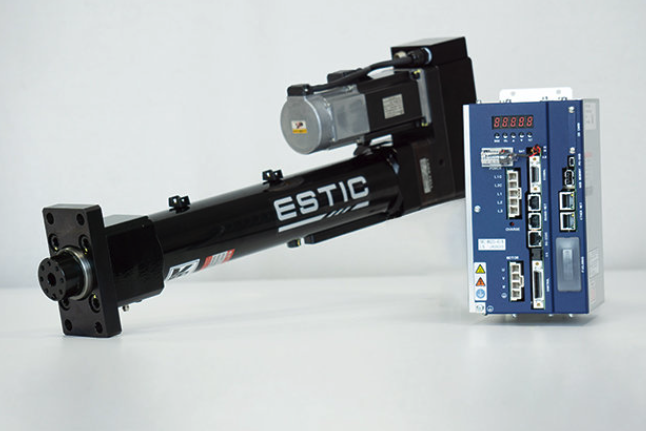

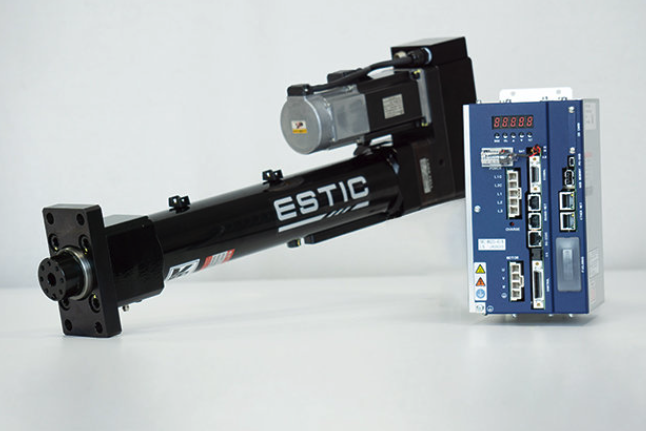

Electric press developed by utilizing control technology cultivated in the development of electric nut runners. Due to its electric drive, it is clean, energy-saving, and fully traceable.

For details, please check the catalog or contact us.

Feature1 Quiet, Clean, and Energy-Saving

Our servo motors are quiet, clean, and energy efficient.

They are envirornmentally friendly, long-lasting, and require virutally no maintenance.

Feature2 Complete Traceability

With up to 100-thousand press curves stored, various data such as NG curves and system error history can be traced.

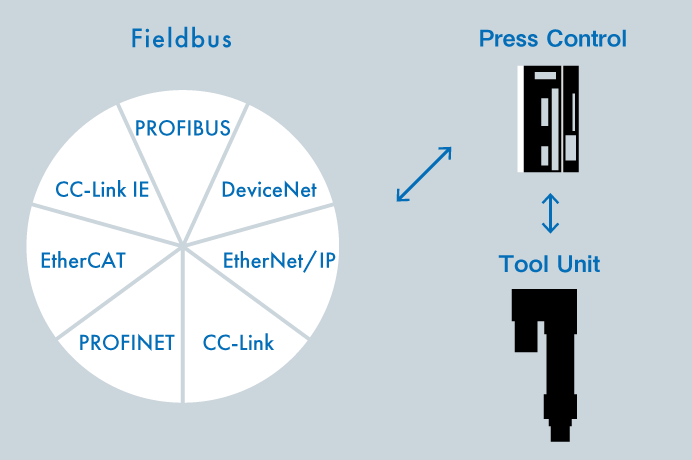

Feature3 Press parameters using Fieldbus

99 types of pressurization parameters are available to flexibly accommodate the set values requested by the customer.

A function to rewrite the pressurization parameter from Fieldbus is also available for those who want to set the parameter more freely. -

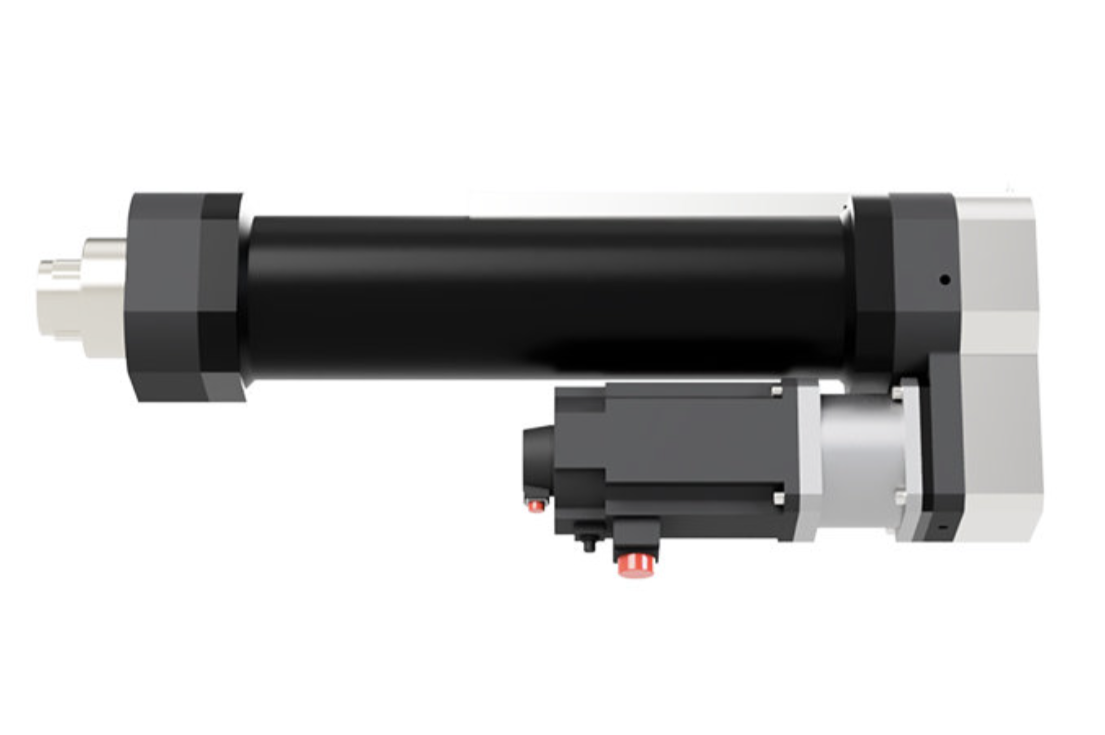

Tool Unit

Three different tool lineups are available.

For details, please check the catalog or contact us.SPT/ SPH Model

SPT Model

This is a low friction standard model that uses a ball spline for the ram guide.

Pressing Capability:5 - 100kN

Consecutive Press Rate:2,1 - 52,4kN

Press Repeat Accuracy:3σ/ X-bar = ± 1.5%

SPH Model

Continuously rated high thrust of a SPT100-30.

Pressing Capability:100kN

Consecutive Press Rate:100kN

Press Repeat Accuracy:3σ/ X-bar = ± 1.5%SPC Model

This compact model is compatible with narrow parts that adopt guide keys and bushes for ram guides.

Press Max. Load:10 - 100kN

Press Continuous Rated Load:4,1 - 42,5kN

Press Repeat Accuracy:3σ/ X-bar = ± 1.5% -

Controller Unit

Control unit that can leave more than 2,000 press-fit results history. Simplified programming specification for selecting an appropriate control method from four preset modes and inputting set values. Use of the management software (optional) enables shortening of the startup time.

For details, please check the catalog or contact us.Communication Technology

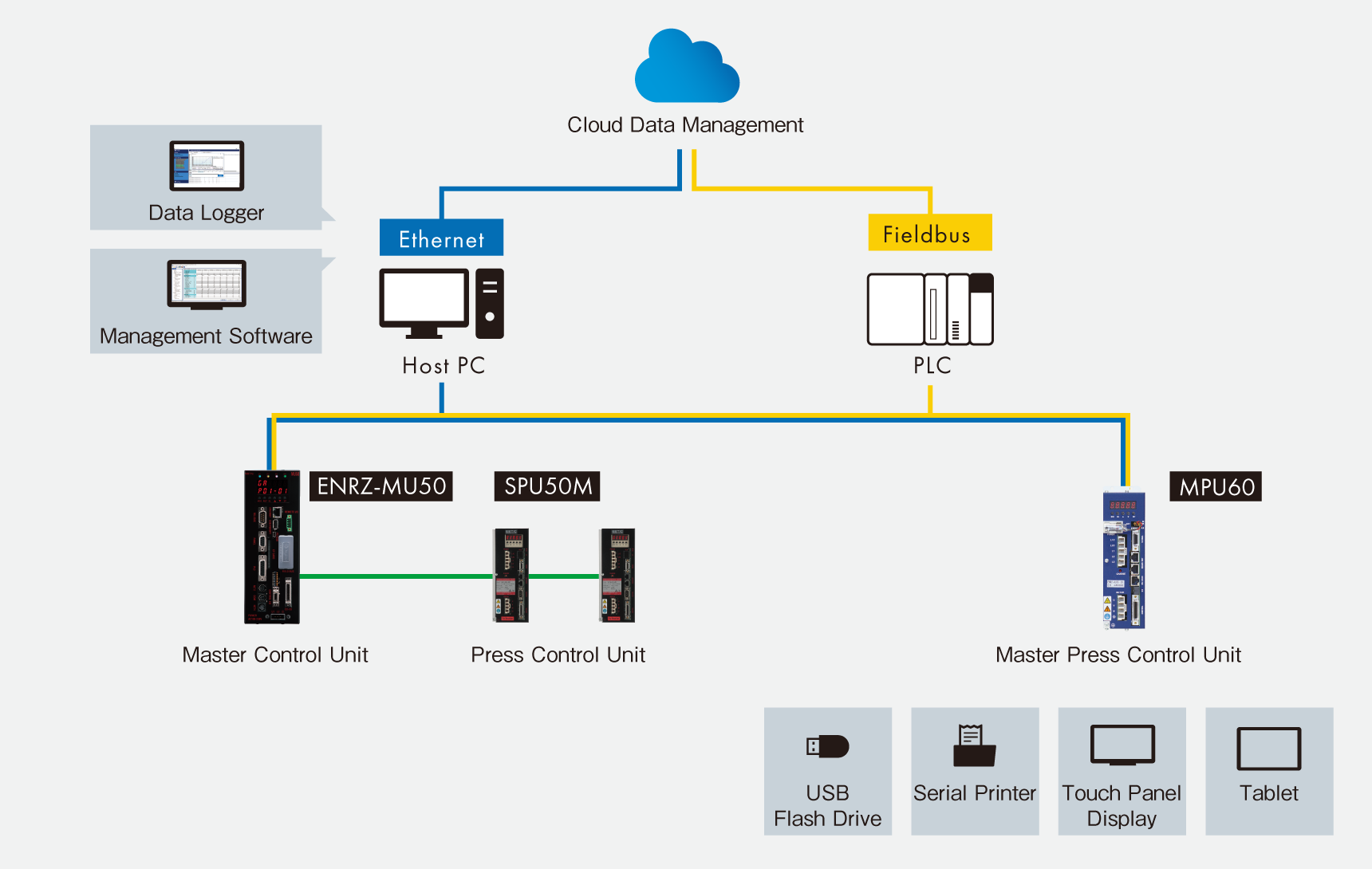

ESTIC's servo press is equipped with a platform that can easily communicate and integrate with host systems through open protocols, etc. Production-efficiency and quality-improvement can be realized by configuring assembly lines mainly for ESTIC's servo press.

MPU60

MPU60

The latest model. 50% smaller from an integrated master controller and press controller. Improve operability with new intuitive user interface.

Pressing Result History: Maximum 100,000

(Varies Depending on Settings)

Pressing Curve History: Maximum 1,000 Curves + 100 of NG Curve (Varies Depending on Settings)

System Error History: Maximum 200

SPU50M/ ENRZ-MU50

Press Control Unit SPU50M

A single-axis control unit developed exclusively for servo presses, realizing high-quality, high-precision pressurization.

Four pressurization methods such as load control position monitor and position control load monitor can be selected.

Master Controller ENRZ-MU50

Core unit for high speed and expandability. Up to 10 press controllers can be connected.

Various Fieldbus modules are available including DeviceNet, Profibus-DP, CC-Link, EtherNet/IP, and Profinet.

Pressing Result History: Maximum 20,000

(Varies Depending on Settings)

Pressing Curve History: Maximum 50

(Varies Depending on Settings)

System Error History: Maximum 200

-

Accessories/ Optional Products

Various accessories and options are available for more convenient use of ESTIC's servo presses.

For details, please check the catalog or contact us.

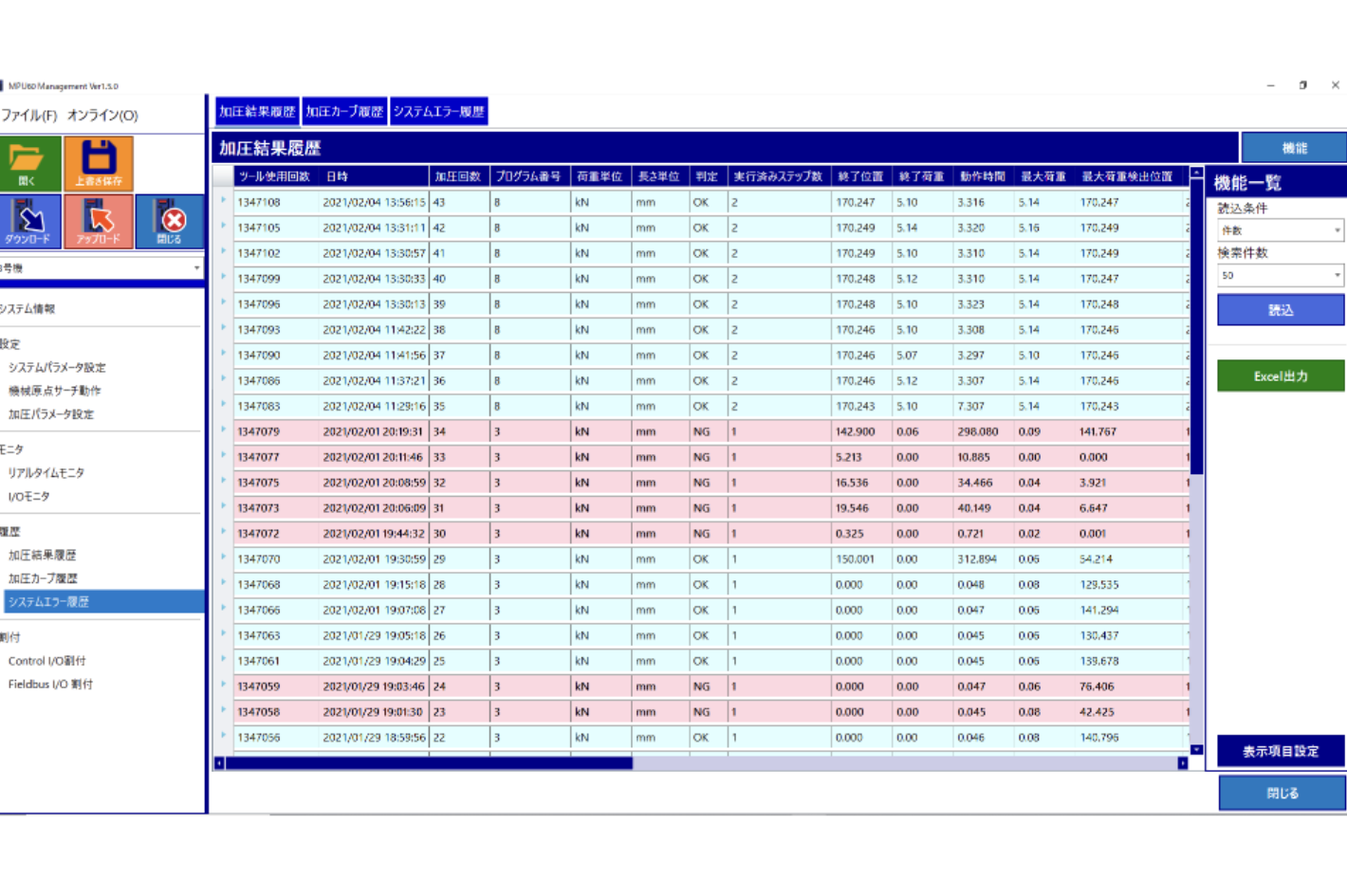

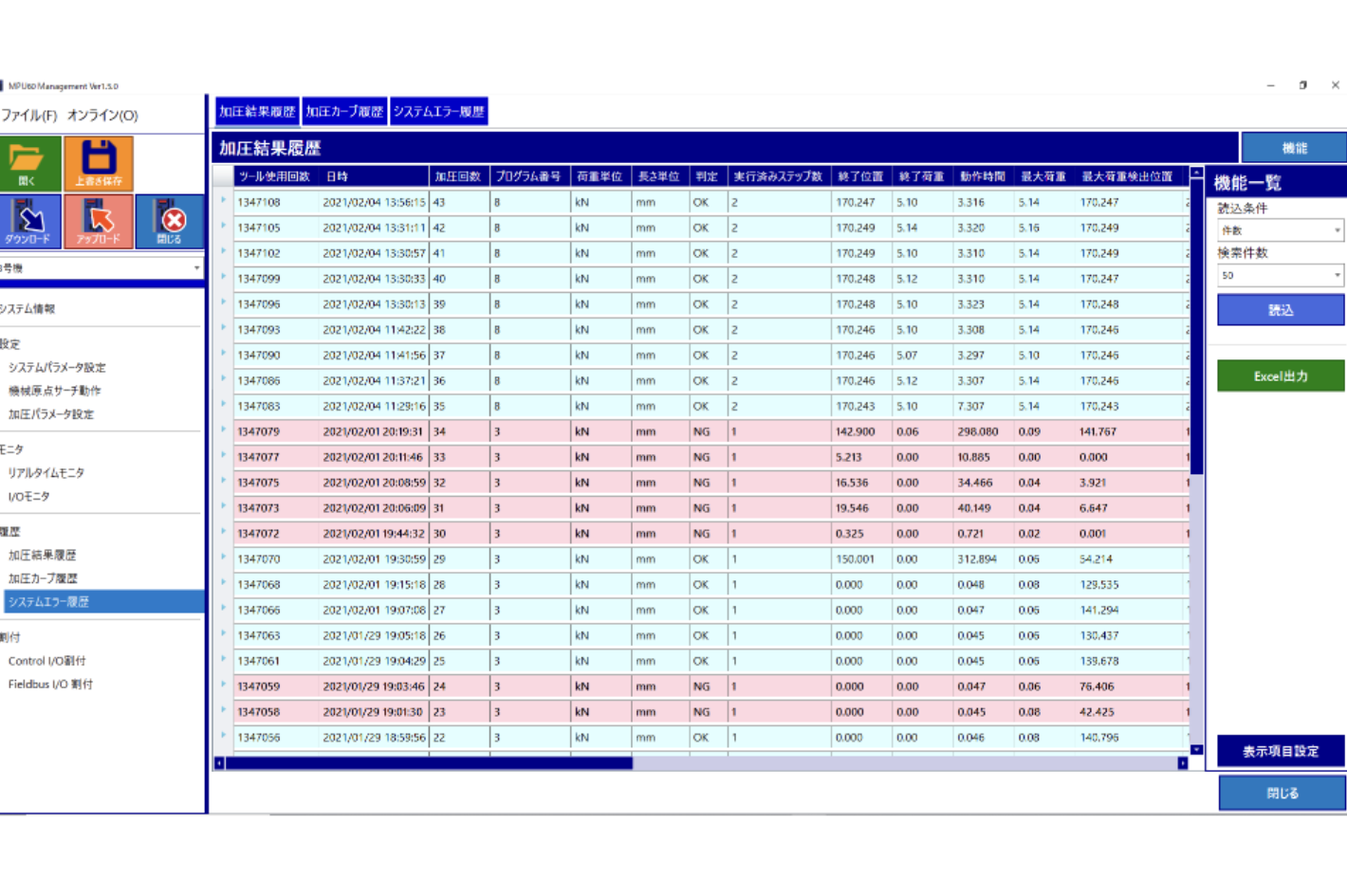

Management Software (For MPU60)

Dedicated support software for all MPU60 models are available.

The software carries out various functions regarding parameters, data storage control, pressurization result monitors, and I/O assignment.

Management Software (For SPU50)

Dedicated support software for all SPU50 models is available.

The program supports functions such as reading/writing of various parameters, data storage control, press result monitor, and I/O assignment.

Data Logger

Automatically collected press data communicates to various controllers via Ethernet.

The data is recorded sequentially in the database and simultaneously displayed on the screen.

The software also batches output acquired press result data in an excel file format on a fixed basis. Report management is easy.

Servo Press

Basick information

Electric press developed by utilizing control technology cultivated in the development of electric nut runners.

Due to its electric drive, it is clean, energy-saving, and fully traceable.

Functions of Servo Press

- Error Detection Function: Mechanism for detecting press fit failure

By combining a load cell (load sensor), an AC servo motor (electric drive), and a ball screw, load and position data (stroke) can be captured, enabling various control.

The stroke speed, position, and load are arbitrarily set to perform press-fit operation and judgement.

Judgment is made in real time while monitoring changes in load and position (stroke) during press-fit operation.

Therefore, it is possible to detect errors such as galling.

- Memory Feature Contributes to Traceability: Various data related to pressurization, such as pressurization results, pressurization curves, and system error history, can be saved, thus contributing to traceability.

- Pressurization parameters can be rewritten from Fieldbus: 99 types of pressurization parameters are available to flexibly accommodate the set values requested by the customer.

For those who want to set the parameters more freely, a function to rewrite the pressurization parameters from Fieldbus is also available.

By combining a load cell (load sensor), an AC servo motor (electric drive), and a ball screw, load and position data (stroke) can be captured, enabling various control.

The stroke speed, position, and load are arbitrarily set to perform press-fit operation and judgement.

Judgment is made in real time while monitoring changes in load and position (stroke) during press-fit operation.

Therefore, it is possible to detect errors such as galling.

For those who want to set the parameters more freely, a function to rewrite the pressurization parameters from Fieldbus is also available.